A150 Turbocharger

A150 Turbocharger

MET Turbocharger

MET Turbocharger

Everllence-NR Turbocharger

Everllence-NR Turbocharger

We can supply Everllence SE (formerly MAN Energy Solutions SE), Mitsubishi Heavy Industries and Accelleron Turbochargers.

| 2-Stroke | MET42MB, MET48MB, MET60MB, MET71MB, MET83MB, MET42MB II, MET48MB II, MET60MB II | ||

|---|---|---|---|

| 4-Stroke | Aftermarket | NR12/S, NR15/R, NR20/R, NR24/S, NR29/S, NR34/S | |

| New building | NR29/S, NR34/S | ||

| TCR14, TCR16, TCR18, TCR20, TCR22 | |||

| A150-M | |||

Turbocharger exclusive production plant

Turbocharger exclusive production plant

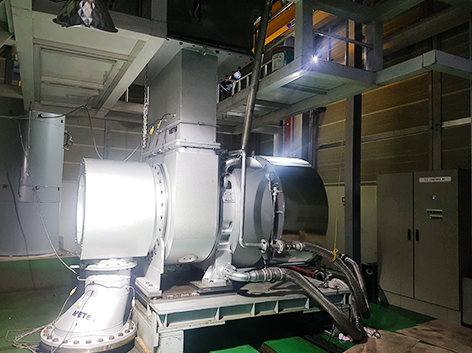

Burner rig test facility

Burner rig test facility

Materials for Turbochargers

Materials for Turbochargers

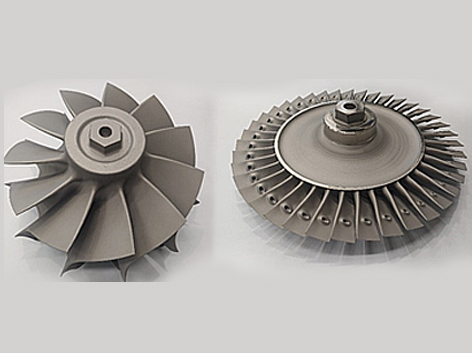

DS (one-way coagulation) blade

DS (one-way coagulation) blade

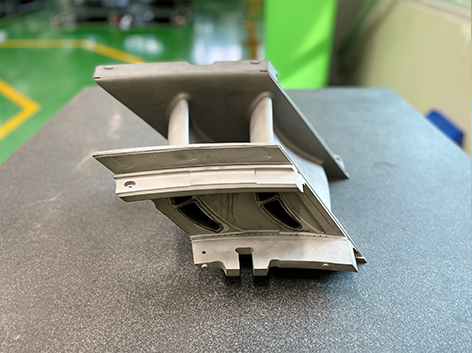

Gas_Turbine(501F_2nd)_Vane

Gas_Turbine(501F_2nd)_Vane

We are developing and manufacturing from gas turbines for power generation to precision casting parts for aviation.

Ni / Co base super alloy casting (EQ/DS/SC)

Materials of the turbocharger for marine

Gas turbine components for power generation

Rotating object parts for defense (Turbine blisk)

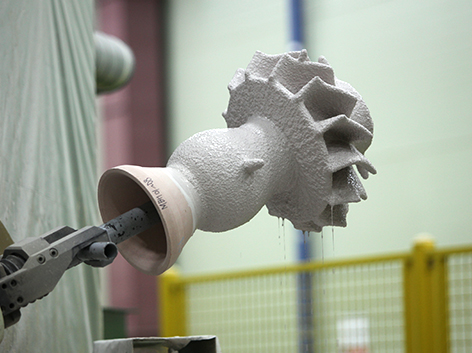

Vacuum precision casting

Vacuum precision casting

Spare Parts Business

Service Business